The DOE is banking that fuel cells can revive Michigan's economy for the long run

Where have we heard this before? Back in 2004 the U.S. Department of Energy (DOE) partnered with Detroit-based DTE Energy to create a $3 million R&D park aimed at making Michigan the epicenter of the sparkling renewable hydrogen economy of the future. Fourteen years later, that still hasn’t materialized. Nevertheless, earlier this month DOE announced a new iteration of the hydrogen effort, this time in partnership with the Michigan Economic Development Corporation.

So, could the second time be the charm?

When at first you don’t succeed . . .

The Michigan Economic Development Corporation expressed significant interest in fuel cell manufacturing as early as 2001, when it commissioned a report under the title, “Positioning the State of Michigan as a Leading Candidate for Fuel Cell and Alternative Powertrain Manufacturing.”

According to the report, the end of the internal combustion engine was in sight, and Michigan would have to replace thousands of manufacturing jobs with, well, something else.

The 2004 venture was actually quite ambitious for its day. Part of a $1.7 billion, five-year plan for hydrogen development under the George W. Bush administration, the project focused on renewable hydrogen.

The hydrogen would be produced by “splitting” plain tap water with an electrical current, a process called electrolysis. The electricity was to be provided by solar or wind power, and therein lies part of the problem: the wind and solar technology of 2004 was more expensive and less efficient than today’s next-generation wind turbines and photovoltaic cells.

Another problem was the electrolysis system. The water-splitting technology of 2004 was not ready for prime time, at least not in terms of commercial viability. Low cost, high-efficiency electrolyzers are only just now emerging within the commercial market.

In 2006 the University of Michigan analyzed the project and found that the facility was already in need of an upgrade. They reported that “the Park, with its current demonstration-stage technologies and costs, is not cost competitive in commercial hydrogen, utility-scale energy storage, or hydrogen vehicle markets.”

DTE was still pitching the R&D effort as a “working prototype” in 2010, but the facility was capable only of producing enough hydrogen for a “small office complex” and a handful of fuel cell vehicles.

DTE’s current website reflects the reality of the situation. While noting the benefits of fuel cells over internal combustion engines, DTE summarizes the technology as follows:

“ . . . fuel cells can power a variety of things, but are still being tested and have not been introduced to market in a large capacity . . . “

Try more and better hydrogen . . .

As disappointing as the Hydrogen Technology Park may be, it does illustrate the importance of maintaining foundational research programs over the long run.

Other public and private sector R&D efforts in the U.S. are beginning to bear fruit. In 2017, for example, GM and Honda announced a partnership to manufacture fuel cells for electric vehicles in Michigan, and other major auto manufacturers are including fuel cell electric vehicles in their lineups.

Fuel cell cars have yet to crack the mainstream U.S. market, but the demand for fuel cell forklifts and delivery trucks is surging.

With all this in mind, the new partnership with the Michigan Economic Development Corporation takes on new significance.

The agreement consists of a memorandum of understanding between MEDC and DOE’s Office of Fuel Cell Technologies Office, aimed at “collaboration on hydrogen and fuel cell research and development (R&D) with the state of Michigan to promote private investment and domestic job creation.”

The MOU provides Michigan stakeholders with access to DOE’s sprawling network of laboratories, with a focus on data collection and analysis.

The idea is to steer R&D efforts into more effective pathways for developing the nation’s hydrogen infrastructure and increasing the amount of hydrogen production.

Or should we say, make that renewable hydrogen!

Ramping up hydrogen production will be a tough nut to crack, without also ramping up greenhouse gas emissions. Currently, 95% of U.S. hydrogen is sourced from natural gas.

Nevertheless, the DOE has set a long-term goal of transitioning out of natural gas and into low or zero emission sources including biogas and solar power. Using waste heat from nuclear power plants is another zero-emission option.

In the solar field, one leading technology currently under consideration for large scale hydrogen production is thermochemical water splitting. The process involves exposing chemically altered water to high temperatures of up to 2,000°C. The heat drives reactions that produce hydrogen. The process is attractive because it can be scaled up by using concentrated solar systems to produce heat with zero emissions. The process also involves no emissions or byproducts, as the chemicals can be re-used in each cycle.

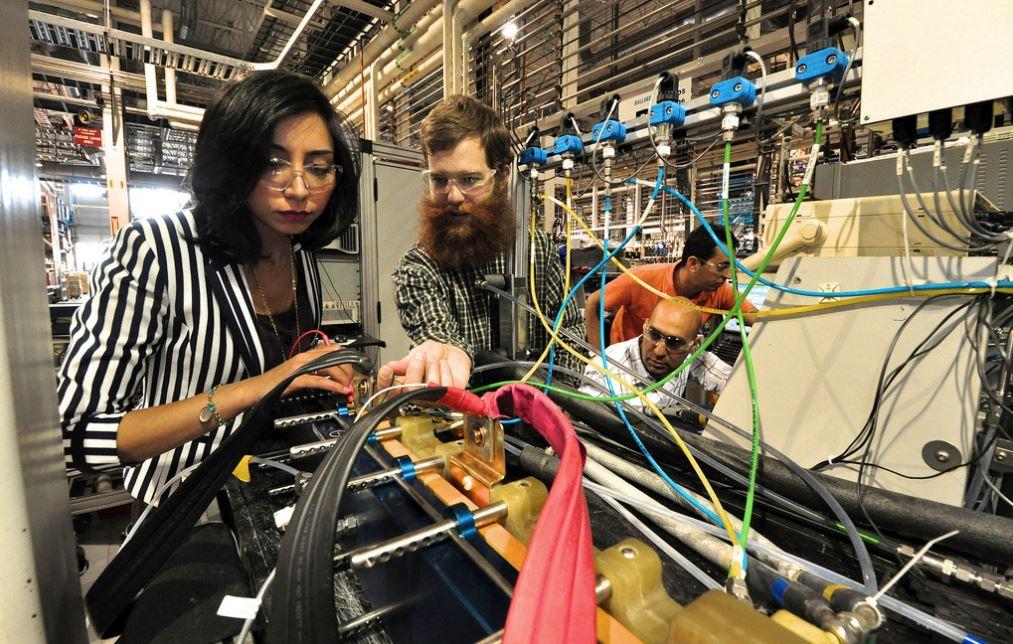

Image credit: DTE Energy

Tina writes frequently for TriplePundit and other websites, with a focus on military, government and corporate sustainability, clean tech research and emerging energy technologies. She is a former Deputy Director of Public Affairs of the New York City Department of Environmental Protection, and author of books and articles on recycling and other conservation themes.