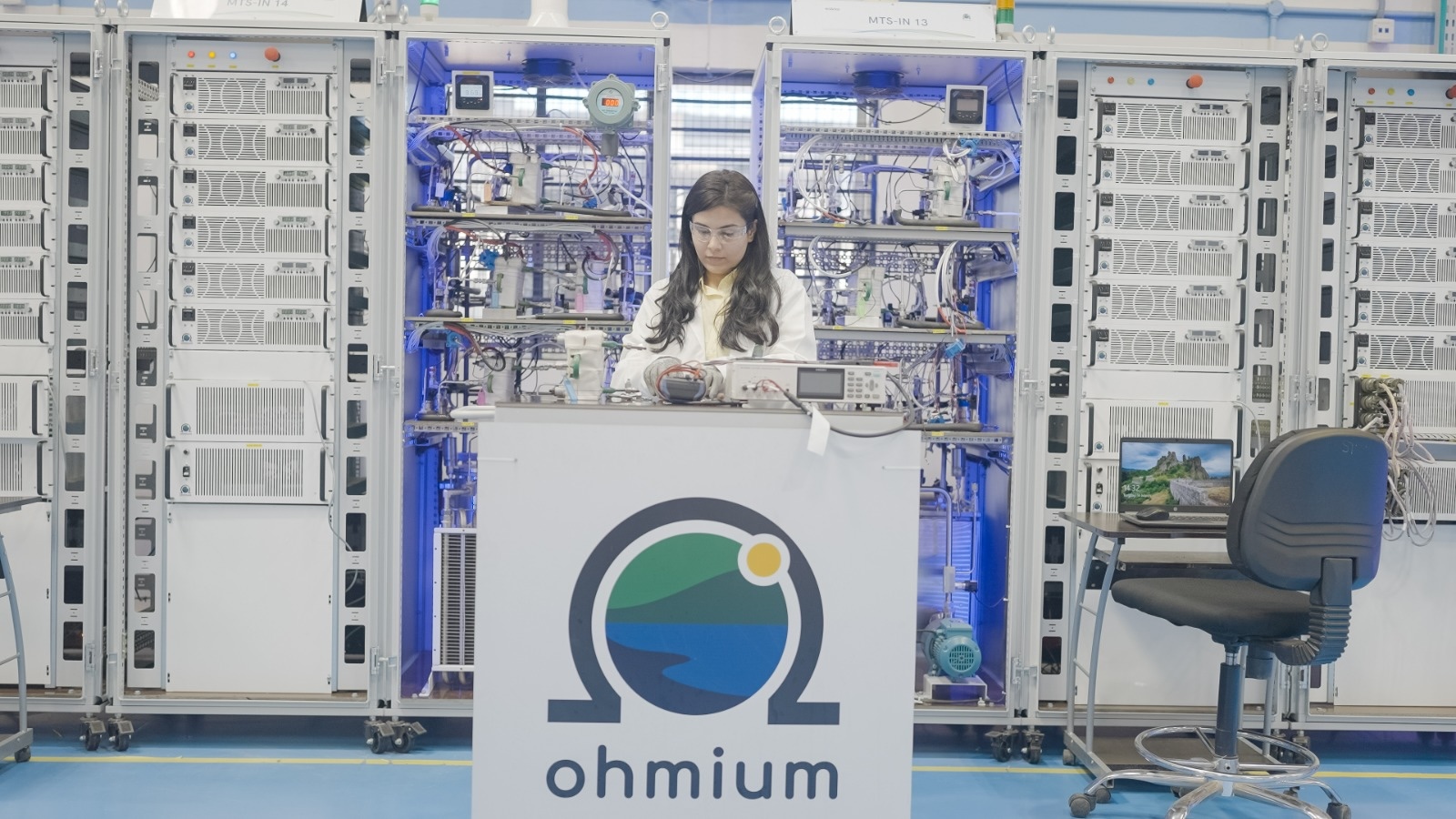

The U.S.-based company Ohmium is working with the offshore wind sector to install equipment that converts seawater into green hydrogen, which can be used for fuel, fertilizers, dyes and more. (Image: Ohmium)

The search for sustainable fuels has entered new territory, as scientists finally crack the code for extracting hydrogen fuel from ordinary seawater. The discovery will help conserve freshwater resources and shift the global economy further away from natural gas as its main source of hydrogen.

Releasing hydrogen from the grip of fossil energy

The vast majority of the global hydrogen supply comes from natural gas, with coal also playing a role. In the U.S., for example, natural gas supplies 95 percent of domestic hydrogen production.

A steep drop in the cost of wind and solar power has begun to change the picture. Renewable energy creates an economical pathway for electrolysis systems, which deploy electricity to jolt so-named “green” hydrogen gas from water. (That's the "H" part of H2O, if you'll recall from chemistry class.)

Green hydrogen is still a new industry, accounting for a small fraction of the overall hydrogen supply — less than 1 percent as of 2022, according to a new report from the International Energy Agency. As the supply of green hydrogen grows, the impact on decarbonization will be significant, because hydrogen is more than a fuel. It also percolates through many elements of a modern, industrialized economy.

To cite just one example, hydrogen is combined with nitrogen to produce ammonia, a key ingredient in the fertilizer widely used around the world. About 80 percent of the ammonia produced today is used for fertilizer. Plastics, dyes, and common household cleansers are among many other ammonia-based products in use today.

Why green hydrogen from seawater?

The rising activity in the green hydrogen field has also focused attention on the freshwater resources needed for electrolysis. Under the current state of electrolysis technology, water must undergo pre-treatment steps to avoid damaging the equipment.

“Electrolyzers require pure (deionized) water for peak performance, long lifetimes, and low overall cost of hydrogen production,” a spokesperson for the U.S. Department of Energy told TriplePundit. "Many of today’s electrolyzers, such as PEM [proton exchange membrane elecrolyzers], have components that are sensitive to contaminants, including minerals and salts in seawater."

Pre-treating freshwater is generally seen as a more economical choice compared to seawater. However, just as biofuel crops raise concerns about food systems, green hydrogen raises questions about freshwater resources. At least 9 kilograms of water (more than 300 ounces) are needed to produce 1 kilogram of green hydrogen, according to one commonly cited estimate.

That concern may become moot as the energy transition progresses. A study published in 2021 describes how green hydrogen could help reduce the overall strain on freshwater resources by replacing fossil energy systems that consume far more water.

Still, attention is beginning to focus on seawater as a practically infinite source that avoids freshwater issues altogether. Seawater could also support green hydrogen development in coastal communities that lack sufficient freshwater.

The offshore wind connection

Researchers are still working on new electrolyzer systems that can use seawater directly, with little or no pre-treatment needed. In the meantime, the U.S. Department of Energy is focusing on research that reduces the cost of pre-treating seawater. With pre-treatment costs under control, it would be more economical to use electrolyzers that are already on the market.

The emergence of the offshore wind industry further bolsters the economic case for seawater purification. Industry stakeholders are already beginning to co-locate offshore electrolysis systems with offshore wind farms. The electrolysis systems can be constructed on platforms within the wind farm or attached to individual wind turbines. Either way, co-location takes advantage of the electricity generated by offshore wind turbines. Without the need for long transmission lines or undersea cables, the wind-generated electricity can be used to power electrolysis systems and seawater pre-treatment systems, too.

Co-location also provides offshore wind farm developers with alternative options for transporting energy from the wind turbines to a point of use. With an electrolyzer on site, offshore wind farms can produce hydrogen gas at sea. The hydrogen can be compressed and loaded onto ships for transportation globally, or it can be sent to shore by undersea pipeline.

In contrast, wind farms without electrolyzers only produce electricity, which must be transmitted to shore by undersea cable. That has already raised transmission issues related to energy loss from cables as well as the risk of disruption or damage.

Co-location would be a particular benefit to coastal economies that lack appropriate sites for constructing electrolyzer facilities and seawater pre-treatment systems on shore. By locating those facilities offshore, green hydrogen stakeholders can avoid competition from other industries for sites on land and objections by local communities or environmental organizations.

Signs of growing activity in the co-location field

France and China have already launched offshore electrolyzer projects. Several more are planned for Japan, Scandinavia and other parts of Europe. All of these projects are still in the demonstration phase, but the advantages of commercial-scale projects are already coming into view.

Over the long run, one of those advantages is cost. In a report published in July 2023, Bloomberg NEF took note of several factors impeding the green hydrogen market, including inflation and competition from fossil resources. Still, Bloomberg analysts projected that those factors will be counterbalanced by the falling cost of renewable energy and electrolyzers.

By the 2030s, it will be cheaper to build new green hydrogen plants than to continue running systems that extract hydrogen from natural gas, the report concluded. Analysts projected that the lowest levelized cost of green hydrogen, meaning the cost compared to other sources, will drop to $1.47 per kilogram in 2030.

In a 2022 report, the International Energy Agency (IEA) projected that costs could drop even further, to a range of $1.30 to $4.50 per kilogram. That is a significant falloff from 2021 when IEA estimated that the current cost of green hydrogen ranged from $3 to $8 per kilogram.

That is also in line with the U.S. Department of Energy, which aims to bring the cost of green hydrogen down to $1 per kilogram in a decade. Currently, the agency estimates a cost of $5 per kilogram for green hydrogen and $1.50 per kilogram for hydrogen sourced from fossil fuels.

Some countries, such as those in the North Sea, already have the advantage of existing offshore wind supply chains and energy infrastructure. Other countries may be attracted by the opportunity to leverage their coasts for renewable energy projects, rather than using scarce land resources.

The energy-water nexus

The U.S.-based electrolyzer firm Ohmium provides one example of the growing interest in offshore co-location. The company settled on a pre-treatment strategy to bring its seawater electrolysis equipment to the offshore wind sector under a partnership with the desalination firm Aquastill.

Arne Ballantine, Ohmium CEO and co-founder, notes that seawater electrolysis is an efficient solution for coastal communities in the U.S., Europe and elsewhere that don’t have adequate freshwater resources but do have access to low-cost renewable energy.

“In Mexico, for example, many industries are built close to ports for access to goods and materials, so that is a nice fit between industries and green hydrogen,” Ballantine told TriplePundit.

Glassmaking is among the industries he mentioned. Glass manufacturers use hydrogen to avoid imperfections and improve the efficiency of cutting and polishing, among other operations. Hydrogen stakeholders in Mexico are advocating for a transition to green hydrogen for the nation’s glass industry and other industrial sectors. Advocates have also taken note of the opportunity to develop green hydrogen as a new export.

“The country has, among other advantages, a privileged geographical location, access to two oceans, a free trade agreement with the United States and Canada, and a large renewable potential,” notes the Mexican Hydrogen Association.

Next steps for green hydrogen

Regardless of the water source, green hydrogen is still fighting an uphill battle on cost. In the U.S. in particular, decarbonization policies can level the playing field. In March, the Energy Department pumped another $750 million into its ongoing clean hydrogen funding program, aimed at reducing the cost of hydrogen from renewable resources down to $1 per kilogram by 2031. The agency has also proposed a new $1 billion program aimed at stimulating demand for clean hydrogen.

U.S. green hydrogen producers also stand to benefit from the “stacking” of tax credits permitted under the 2022 Inflation Reduction Act. According to a Platts analysis cited by S&P Global last fall, green hydrogen producers could see their costs sink into negative territory, at least until the tax credits expire in 2033. By then, tax subsidies would no longer be needed to reach price parity with conventional hydrogen, as projected by Bloomberg and the IEA. The expiration of the tax credits also tracks with the Energy Department’s goal of $1 per kilogram by 2031.

As the world grapples with the twin threats of climate change and water scarcity, co-locating electrolysis systems with offshore wind farms has emerged as a pathway for conserving freshwater resources while decarbonizing large swaths of the global economy, and investors in some countries are already exploring the technology.

That has yet to occur in the U.S., where the opponents of offshore wind development have succeeded in blocking all but a handful of offshore wind turbines so far. The prospects look brighter with renewed support from the Joe Biden administration, but it remains to be seen if public policy continues to support the renewable energy transition after the 2024 election cycle. Scientists, engineers and investors are doing their part. The rest is up to the voting public.

Tina writes frequently for TriplePundit and other websites, with a focus on military, government and corporate sustainability, clean tech research and emerging energy technologies. She is a former Deputy Director of Public Affairs of the New York City Department of Environmental Protection, and author of books and articles on recycling and other conservation themes.