Multinational consumer goods company Procter & Gamble has ramped up its efforts around minimizing plastic waste—and one of its scientists recently invented a new recycling technology that the company is keen to share with the world. TriplePundit spoke with Virginie Helias, chief sustainability officer for Procter & Gamble, to learn more about the technology—and how it fits in with P&G's broader mission to tackle plastic waste.

A new recycling solution

It may come as news to some, but plastic bottle caps are typically made from a different material than the rest of the bottle. Plastic beverage bottles, for example, are made from polyethylene terephthalate (PET), while the caps are made from polypropylene (PP or Plastic No. 5).

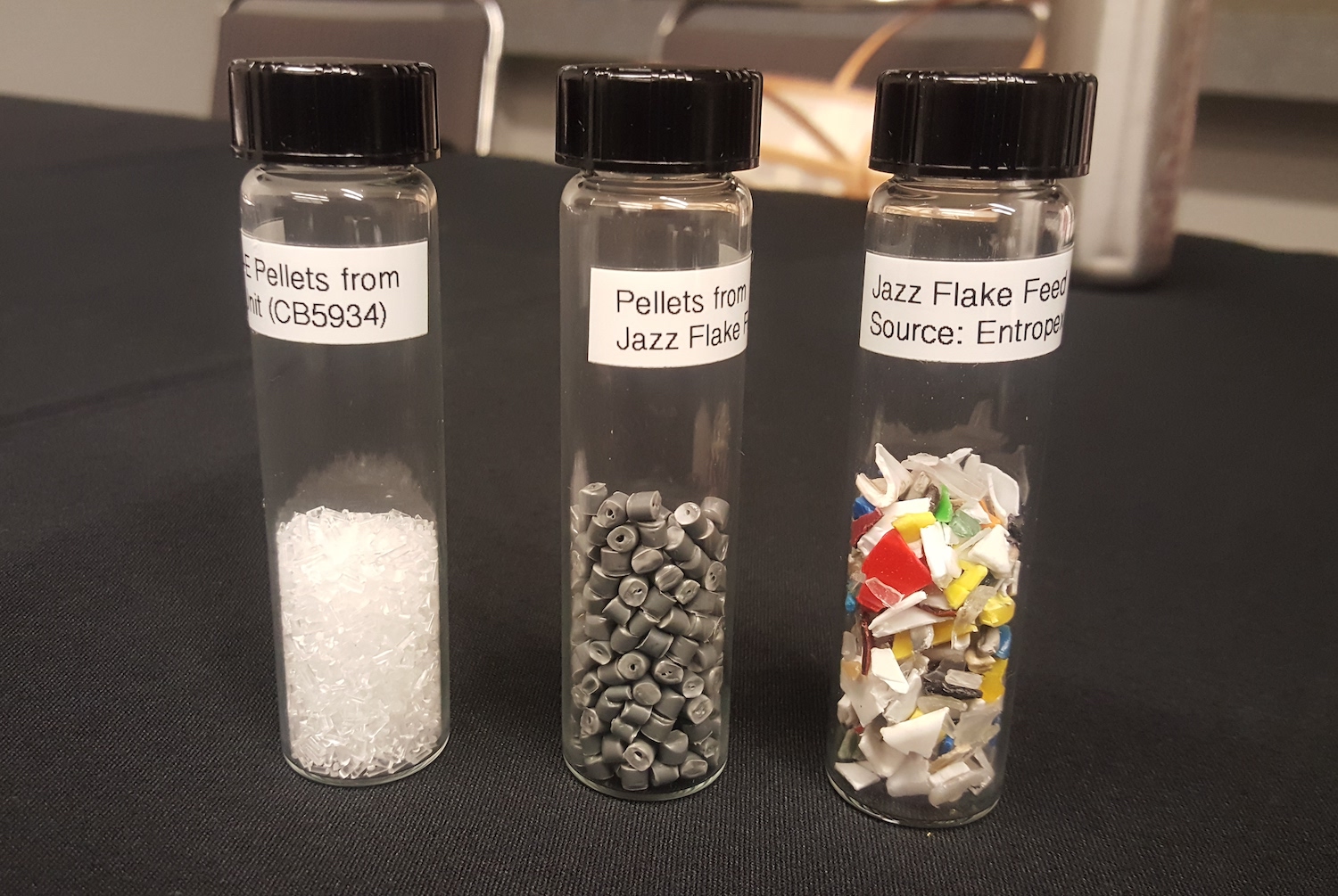

Polypropylene, a rigid plastic, is also used to package common household products like yogurt and laundry detergent, but recycling it remains a challenge. To put it simply: When PP is processed, the resulting material is opaque and dark in color. Typically, the only end use for this material is to down-cycle it into products like park benches or flower pots, significantly lowering its value in the recycling market.

Last year, a Procter & Gamble scientist devised a solution to change all that. John Layman, section head of corporate research and development for P&G, and his team figured out a way to remove all colors and contaminants from recycled polypropylene, essentially returning it to its virgin state. The resulting material is clear, "so you can use it for another bottle or cap," Helias told us at the Sustainable Brands conference in Detroit last week. "It's a really powerful technology."

(Image: The vial on the far right is filled with shredded polypropylene plastic. The vial in the middle contains flake created through existing polypropylene recycling methods, and the vial on the left—filled with clear plastic—is recycled polypropylene made with P&G's new process.)

The discovery was born out of a meeting with the North American Association of Plastic Recyclers, which convened manufacturers to discuss which types of recycled plastic they're looking to buy—and which types they have trouble sourcing. "They realized that recycled polypropylene was in high demand, and if we could get to a virgin quality, then there would be many manufacturers who would place big orders at a very good price, creating the demand and creating the supply," Helias told us. "We developed our process because we realized there was a market for it."

At a commercial facility set to open in Ohio next year, PureCycle Technologies will utilize P&G's process to recycle polypropylene and sell the resulting feedstock to any and all buyers. P&G also open-sourced the technology so other companies can replicate it.

"Innovation is critical so that we can accelerate the circular economy," Helias said. "But the problem is that all of this took many years." A new partnership has the potential to change that by calling on companies that use plastic in their supply chains to share innovations and best practices.

(Image: Virginie Helias, chief sustainability officer for Procter & Gamble, speaks at the Sustainable Brands conference in Detroit.)

A new partnership can help plastic solutions scale

Last month, P&G became the first brand to join the World Wildlife Fund's ReSource: Plastic collaborative. ReSource is similar to the U.N. Sustainable Development Goals (SDGs), in that it seeks to translate disparate goal-setting into a common language—in this case, around preventing plastic waste.

"ReSource is basically a platform that will help develop common language, common metrics and common understanding of the best practices—and really, in the end, collective accountability," Helias explained.

Additionally, this type of platform can help stakeholders realize which technologies and processes they're missing—and deploy solutions like P&G's faster and at scale, Helias continued. "ReSource could dramatically increase the speed of identifying the needs of an industry and developing a scalable solution," she told us. "That's the real beauty of such a platform."

The new platform builds on the success of other multi-stakeholder partnerships around plastic, such as the Closed Loop Fund and its efforts to boost municipal recycling and the Ellen MacArthur Foundation's New Plastics Economy with its mission to drive circular solutions for plastic. The WWF estimates that as few as 100 companies could prevent 10 million metric tons of plastic pollution through this type of collaboration.

(Image: These P&G products are now available in refillable packaging through Loop.)

Collaboration drives reuse forward

For P&G, which is a member of both of these coalitions as well as ReSource, recycling innovations are only a part of the overall push to end plastic waste. The company has set a number of bold goals around plastic under its Ambition 2030 plan—from halving its use of virgin plastic by 2030 to ensuring no P&G plastic finds its way to the ocean. As with recycling innovation, realizing goals like these often hinges on collaboration, Helias told us.

For example, P&G became one of the first brands to join Loop, a startup that delivers common household products in reusable packaging. Founded by New Jersey-based recycling company TerraCycle, Loop essentially returns to the milkman model by delivering common products—in refillable packaging—straight to the user's door. When the package is empty, the user simply places it in a reusable tote, and it's picked up, sanitized and sent back to someone else.

P&G has made several of its most popular brands available through Loop, including Pantene, Tide, Cascade and Oral-B, and it's calling on other companies to do the same. "I have very, very early results, and what we are seeing as a trend is: The broader the lineup, the more likely people are to order," Helias said. "That’s why we need collaboration from many more brands. It's a new era of brand-building and marketing where the more of you there are, the more successful you will be."

Additionally, P&G is piloting another refillable option for its Olay skincare brand in the U.S. and U.K. Beginning in October 2019 and running through the end of the year, the company will offer its best-selling Olay Regenerist Whip moisturizer with a refill pod that fits into the jar. The refill has the potential to eliminate 1 million pounds of plastic over three months, given buying trends for the product, according to P&G.

(Image: One of P&G's most popular skincare products will be available in refillable packaging starting this fall.)

"Loop is very easy for the consumer. She or he doesn't have to do anything—just pick up the order, use the product and order the pickup," Helias said. "With Olay, it's a different type of refill system we are learning about, which is that she has to do the refill herself. It's a three-month test, because there’s a lot we need to learn—will she be willing to buy these pods and do the refill?"

Coming together to understand the circular economy

Offering more sustainable versions of its most popular products is more than a one-off for companies like P&G—it's an opportunity to engage customers in the fight against plastic waste and learn more about their habits, Helias said.

"We still have to learn a lot about consumer adoption and about circularity in the supply chain," Helias told us. "We could not have done Loop six, seven or eight years ago. People were not ready. But we've seen in all of our research that more and more people are saying they want to buy responsibly and they want to use their products responsibly. There is clearly a very high growth in consumer expectations, so the time is right."

Images: Catherine Sheila and George Becker/Pexels, Mary Mazzoni, Procter & Gamble

Mary has reported on sustainability and social impact for over a decade and now serves as executive editor of TriplePundit. She is also the general manager of TriplePundit's Brand Studio, which has worked with dozens of organizations on sustainability storytelling, and VP of content for TriplePundit's parent company 3BL.